Trailer torsion axles have rubber suspension inside, a steel torsion bar surrounded by 4pcs rubber cords, axle tube welded 2pcs bracket on left and right side, axle head assembly lazy hubs or brakes system. That easy to install and better suspension performance, mainly used for the trailers that need good performance suspension, such as camper trailers, boat trailers, solar light trailers, equipment trailers.

Additional information

| Trailer Parts | Boat Trailer Torsion Axles |

|---|---|

| Load | 3,500 lbs, 5,200 lbs, 6,000 lbs, 7,000 lbs, 8,000 lbs |

| Track | 86"/72", 92-1/2"/80", 95"/80 |

| Surface | Gal. / Dacromet |

| Brakes | Integral Rotor Brake, Slip Rotor Brake |

| Replacement | U.S Axles |

| Manufacturer | Made in China, Mastervim |

我是标签内容,点击编辑按钮更改此文本。Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

我是标签内容,点击编辑按钮更改此文本。Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Capacity 3,500lb / Capacity 5,200lb / Capacity 6,000lb / Capacity 7,000lb / Capacity 8,000lb

Trailer torsion axles have rubber suspension inside, a steel torsion bar surrounded by 4pcs rubber cords, axle tube welded 2pcs bracket on left and right side, axle head assembly lazy hubs or brakes system. That easy to install and has better suspension performance, mainly used for the trailers that need good performance suspension, such as Camper trailers, Fifth-wheel trailers, Off-road trailers, Toy hauler trailers, Double-decker trailers, Caravan towed trailers, Solar trailers, Horse trailers, Jeep trailer, Lowboy trailer, Mobile Home, Pup up trailer, Dolly trailer, Tow dolly, Car hauler, Construction trailer, Genset trailer, Generator trailer, Snowmobile trailer, Boat trailer, Aluminum trailer, Utility trailer, Light duty trailer, etc.

Details

- used for trailers max. capacity 8,000lb.

- forged swing arm with spindle

- grease lubrication set on rubber hub cup

- brakes 10″ 12″ and 13″ hydraulic brakes

- removable spindle and welded spindle optional

- swing arm angle customized, such as +30 +23 +10 0 -10 -23 -30

- black powder coating and galvanized treatment optional

- V bend shape

- complete kit assembling

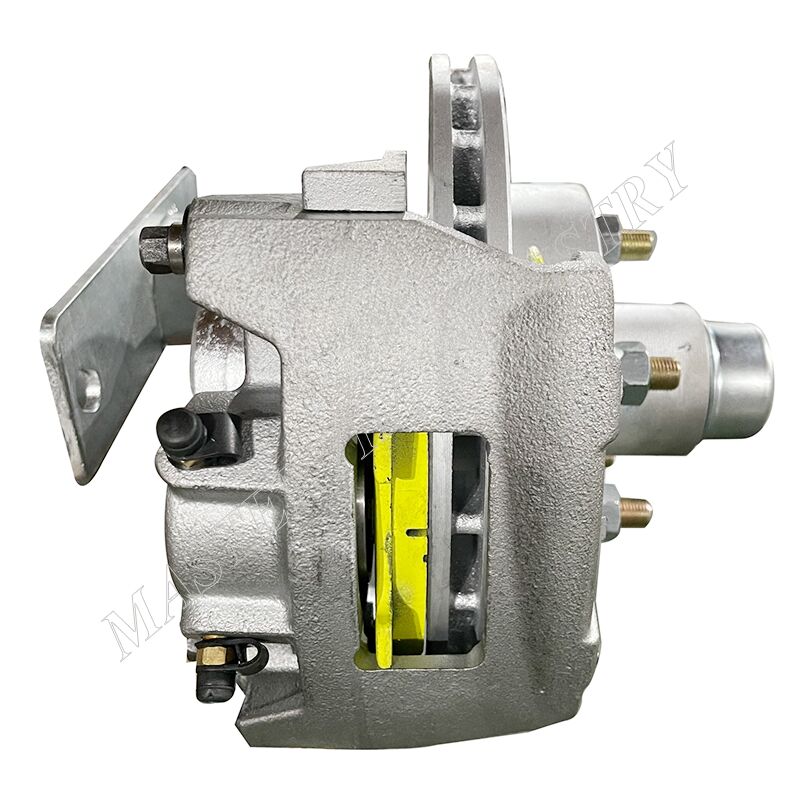

- slip over brake axles: 1x axle, 2x lazy hubs, 2x rotors, 2x calipers, 2x brackets, and nuts bearing, oil seal, washer, pin, cup

- integral brake axles: 1x axle, 2x hub rotors, 2x calipers, 2x brackets, and nuts, bearing, oil seal, washer, pin, cup

Torsion axles VS tube spring axle

Dependable: The torsion axle uses a seamless steel tube, rubber cords, solid torsion bar, and forged swingarm, the axle components have higher strength.

Independent suspension & smooth ride: torsion end unit to stand suspension travel and shock absorption, each wheel works independently from the other side.

Without metal impact & no-noise: Rubber cords connect the torsion bar and axle tube, so when the trailer running, the inner rubber stands the impact and recovers to the original position. Regarding leaf spring axle, commonly, U bolts connect axle leaf spring with trailer frame, so all metal parts impact on a bad road condition.

Adjustable ground clearance: torsion axles could adjust the swingarm angle to change the ground clearance, sometimes, such as the car carrier trailer, needs as lower as possible on ground clearance, so the swingarm needs to have a negative angle. Regarding the boat trailer, due to the boat’s V shape, so can’t let the boat bottom to close with the group, sometimes, the swing angle is at a positive angle.

Maintenance fee: torsion axles don’t have to use leaf spring, U bolts, and mounting plate. As we know, leaf spring belongs to easy-wear parts, and is easier rusty, especially you often tow a trailer and live at the seaside. The most important factor is users have to use the trailer until the trailer shop finishes repair.

Boat trailer torsion axles all come with anti-corrosion surface treatment, including axle tube, torsion bar swing arm, and brake kit.

Disc brakes VS drum brakes

A disc brake has more of a 35%-50% touch area than a drum brake, so that has unique brake strength compared to a mechanical drum brake and hydraulic drum brake. I add that, commonly, disc brakes with vented holes for cooling, so whatever consider brake performance or thermal decay, no doubt, disc brake will be a leader compared to old brake methods such as drum brakes.