Product Process

🔧 1. Raw Material Preparation

🏗️ 2. Component Forming

🧪 3. Welding and Assembly

🛠️ 4. Surface Treatment

🧪 5. Testing and Quality Control

📦 6. Final Assembly and Packaging

A brake chamber is a critical component in air brake systems, commonly used in heavy-duty vehicles like trucks and buses. It converts compressed air pressure into mechanical force, pushing a rod that applies the vehicle’s brakes. There are two main types: service chambers (for normal braking) and spring brake chambers (which also provide emergency and parking brakes).

| Size | T20, T24, T20/24, T24/24, T30, T24/30, T30/30 |

|---|---|

| Cross Brand | Wabco, Bendix, Knorr-Bremse, Haldex, Meritor, TSE, Sealco, FUWA, Sorl, MASTERVIM, Sauer |

A brake chamber is not just any component; it is the heart of the air brake systems utilized in heavy-duty vehicles such as trucks and buses. This essential piece of equipment plays a pivotal role in ensuring the safety and effectiveness of braking mechanisms under various driving conditions.

Brake chambers convert compressed air pressure into mechanical force. When the driver activates the braking system, air is directed into the brake chamber, causing a diaphragm to flex. This flexing pushes a rod that applies the vehicle’s brakes. This seamless process ensures that the vehicle slows down or comes to a complete stop effectively, making it a crucial element for road safety.

There are primarily two types of brake chambers: service chambers and spring brake chambers. Service chambers are responsible for normal braking functions, facilitating the everyday stopping needs of the vehicle. On the other hand, spring brake chambers are engineered to provide additional safety. They not only assist in standard braking but also engage emergency and parking brakes, offering dual functionality. This hybrid capability is particularly important for heavy-duty vehicles often subjected to challenging terrains and loads.

Choosing the right brake chamber for your vehicle is vital for optimal performance. Whether you require a robust service chamber for standard use or a spring brake chamber for added safety features, understanding the differences will help you make a more informed decision. Evaluate your vehicle’s specific needs and ensure that the brake chamber you select meets safety standards and performance expectations.

Ultimately, brake chambers are indispensable for anyone involved with heavy-duty vehicles. With proper maintenance and timely replacements, you can ensure the longevity of your braking system and, more importantly, the safety of all road users.

A brake chamber is a critical component in air brake systems, commonly used in heavy-duty vehicles like trucks and buses. It converts compressed air pressure into mechanical force, pushing a rod that applies the vehicle’s brakes. There are two main types: service chambers (for normal braking) and spring brake chambers (which also provide emergency and parking brakes).

The brake chamber production process typically involves the following key steps:

Steel sheets or tubes are selected for the chamber shell and push rod.

Materials are cut and shaped using CNC machines, laser cutters, or press machines.

Shell stamping/forming: The upper and lower halves of the chamber are stamped into shape using molds.

Push rod machining: The rod is cut, threaded, and shaped for precise movement.

Shell parts are welded or crimped together, depending on design.

Internal parts such as springs, diaphragms, and seals are assembled carefully.

Components are cleaned, then coated with anti-corrosion treatments such as powder coating, zinc plating, or electrophoresis.

Each unit undergoes air pressure leak tests, spring tension tests, and stroke checks to ensure proper function.

Some are subjected to life-cycle fatigue testing.

The fully assembled brake chamber is labeled, serialized, and packaged for distribution.

Explanation

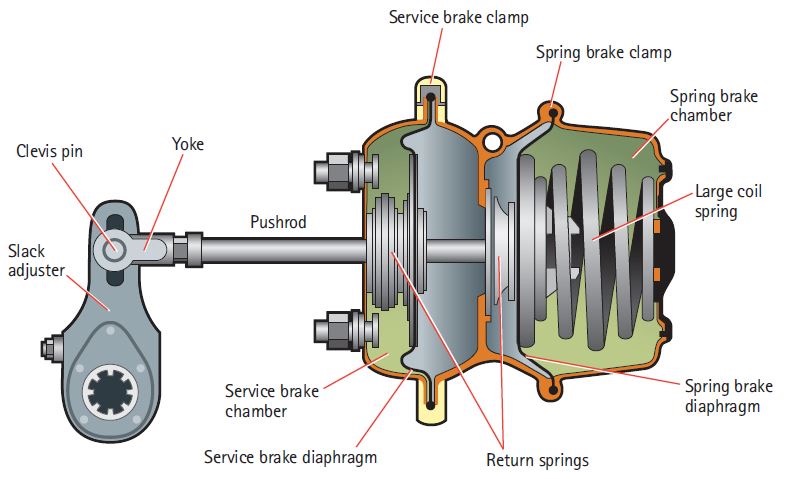

The air brake chamber (Peters, 2015, p. 10).

The two main components in an air brake system are the compressor and the spring brake chamber. When the air governor detects that the pressure in the system is below 90 pounds per square inch (PSI), it sends a signal to the compressor to fill the storage tanks with the appropriate amount of air. The governor stops the compressor when the pressure in the system “reaches approximately 125 pounds per square inch.” The governor ensures that the pressure in the system is always at a safe level (Peters, 2015, p. 9).

The air is routed to brake chambers located near the wheels through air lines. The video outlines this process in a detailed manner at the four minute and 33 second mark (link). Essentially, the air and the springs in the brake chamber provide an equal force against each other when the system in a neutral position and the vehicle is rolling freely. However, the brakes are applied if the operator uses the foot pedal to introduce air into the brake chamber. The air pressure is greater than the force exerted by the service brake return spring, and thus the brakes are applied to the rear wheels when the pushrod is moved out of the chamber. Similarly, if the air pressure is not sufficient enough to act against the force exerted by the emergency spring brake, the spring brake will be engaged. This ensures that the vehicle will stop if the system loses air pressure (Peters, 2015, p. 9; “Lessons in School Bus,” 2008).

WABCO (now part of ZF)

Global leader in commercial vehicle braking systems.

Known for quality and innovation in air brake components.

Bendix

North American brand, highly trusted for brake chambers and air brake systems.

Offers spring brakes, service chambers, and complete brake solutions.

Knorr-Bremse

German brand with a strong presence in Europe and Asia.

Offers durable and precision-engineered brake components.

Haldex

Swedish brand focusing on air brake systems for trucks, trailers, and buses.

Known for spring brake chambers and actuators.

Meritor

U.S.-based company known for brake chambers, axles, and drivetrain components.

Supplies OEM and aftermarket solutions.

TSE Brakes

Specializes in premium spring brake chambers with patented UltraLife designs.

Sealco

U.S. brand known for air brake valves and chambers, used often in trailers.

FUWA

Chinese manufacturer offering cost-effective brake chambers and suspension systems.

Sorl

Another major Chinese brand with a growing global market in commercial vehicle braking systems.

MASTERVIM

Established OEM suppliers in China, with brake chambers certified for domestic and export markets.

Mastervim is an original manufacturer of trailer axles and brakes. No matter what style of axles & brakes you want, based on our extensive experience, we can manufacture it.

Mastervim will only notify you by email when a new product is launched

We will contact you within 1 working day, please pay attention to the email with the suffix “@mastervim.com”.