Mastervim developed Aluminum Hitch Receiver Balls Assembly for top grade market that used for luxury car trailers.

Additional information

| Item | Aluminum trailer hitch receiver |

|---|---|

| Size | 2-5/16", 2'' |

| Load | 12,000 lbs., 8,000 lbs, 18,500lbs |

| Surface | Black, Original, Red |

| Warranty | 3 years |

| Manufacturer | Mastervim |

我是标签内容,点击编辑按钮更改此文本。Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

我是标签内容,点击编辑按钮更改此文本。Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SAE J684 tested aluminum adjustable drop hitch !!!

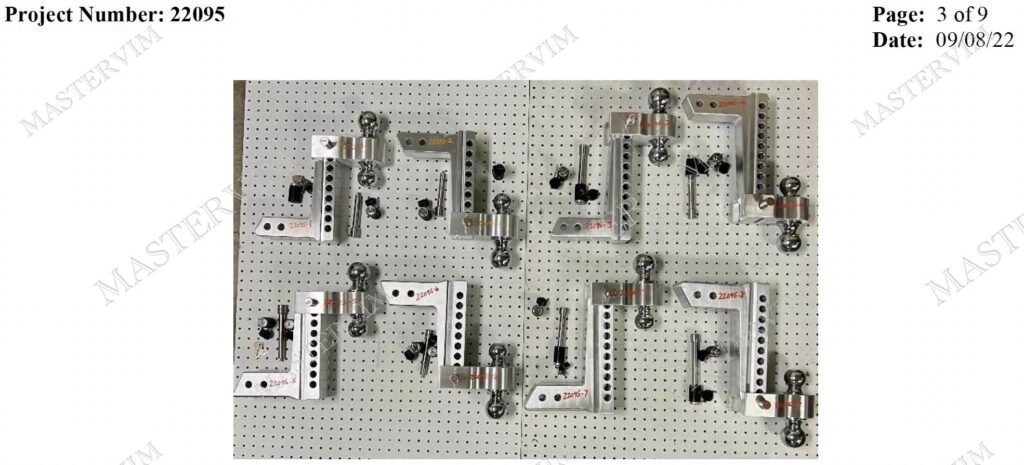

Test Samples

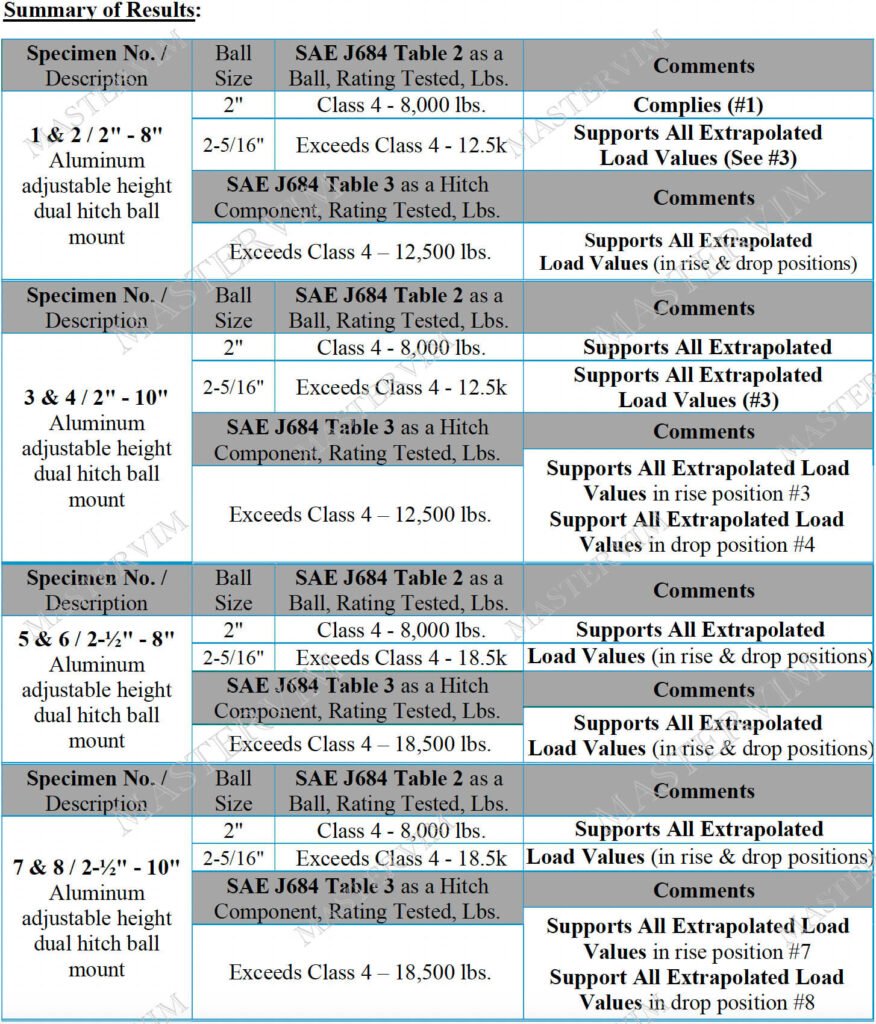

Test Result

Aluminum Coupling Test Standard

- Vertical Tension Load Requirement—The vertical tension load requirement is extremely important because of the mechanics of holding the ball in the socket. On vertical-tension (or pullout) testing, the major portion of the tensile load is transferred from the lip of the coupling to the ball clamp and its supporting bolt, rivet, or inclined plane. While relatively little distortion occurs in the coupling housing, the ball clamp is forced back and downward until the final restricting force retaining the ball is lost and pullout occurs. The load at which retention is maintained is highly critical and loss of purchase on the ball occurs suddenly, going from safe retention to complete separation.

- Coupling versus Hitch Static Bench Test Load Requirements—Coupling strength design criteria are necessarily different than those for hitches and will be greater because of the stresses to which each is subjected. Couplings are welded or bolted to trailer tongues with only the socket and latching mechanism exposed. The coupling socket must take the concentrated dynamic shock load as well as the varying stresses induced from normal trailering and is the point of highest stress. The hitch load is distributed through the hitch components, spring deflections in the towing vehicle, shock absorbers, and the vehicle structure, and is affected by an entirely different force distribution than the coupling. Hitches are actually subjected to much lower unit forces than the coupling and the ball.

-

Longitudinal Tension: Gross trailer Weight, N (lb) x 3

- Longitudinal Compression: Gross trailer weight, N (lb) x 3

- Transverse Thrust: Gross trailer weight, N (lb) x 1

- Vertical Tension: Gross trailer weight, N (lb) x 1.3

- Vertical Compression: Gross trailer weight, N (lb) x 1.3

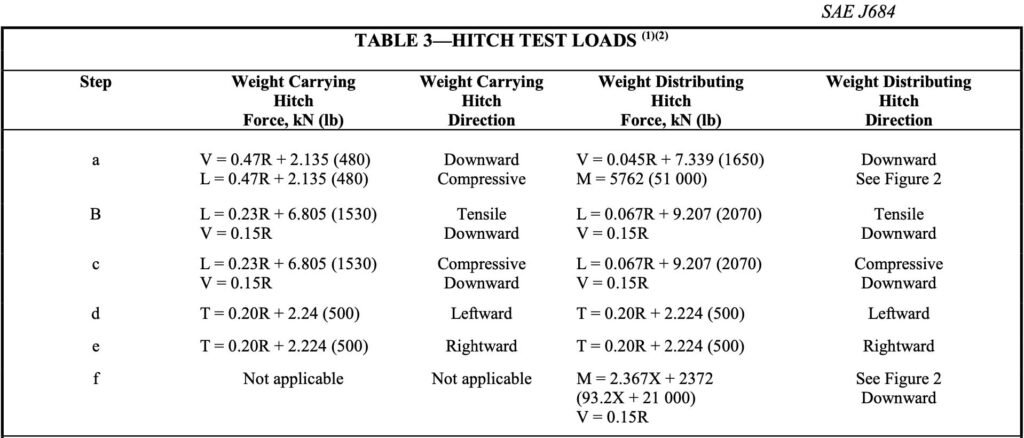

V = Vertical Force (N [lb])

L = Longitudinal Force (N [lb])

T = Transverse Force (N [lb])

M = Spring Bar Moment (N · m [in-lb]) (Leveling Force Couple)

R = Hitch Rating in terms of trailer GVWR (N [lb]) (Gross Vehicle Weight Rating) X = Hitch Rating for Maximum Vertical Load on Hitch (N [lb]) (Tongue Weight)

Packing list

Trailer Drop Hitch Ball Mount

Drop 4″, receiver 2″, 12,000lb, 7.5kgs, 100pcs/ pallet, 1.6cbm

Individual Carton Size: 320x315x160mm

Drop 6″, receiver 2.5″, 18,500lb, 11.4kgs, 70pcs/pallet, 1.6cbm

Individual Carton Size: 360x310x160mm

Shackle

Receiver 2″, 10,500lb, 2.5kgs, 300pcs/pallet, 1cbm

Receiver 2.5″, 13,000lb, 3.5kgs, 300pcs/palllet, 1cbm

Color optional, MOQ 100pcs.

Load capacity experienced on tensile testing machines.

Warranty 3 years, not including surface painting.

Hitch test loads:

3 times weight-carrying hitch, maximum trailer GVWR to be drawn.

1.3 times vertical tongue weight to be imposed on the ball.